Posted on January 8, 2026 by Jake Marrs and Savita Bowman

Carbon dioxide (CO2), once seen as an industrial by-product, is becoming a valuable American commodity. It was first used in the 1970s for enhanced oil recovery (EOR), injected underground to extract additional crude oil from oil reservoirs. While EOR remains an effective tool, the range of use today for captured CO2 has expanded – strengthening the economy and supporting sectors at the heart of U.S. growth, including fuels, construction and agriculture.

The market for products utilizing CO2 is rapidly emerging as a key part of America’s industrial and energy economy, with global revenue projected to exceed $1 trillion by 2040. Many companies are now turning innovation into a competitive advantage, transforming by-products into feedstock for carbon-based materials, fuels, chemicals and even consumer goods like On Cloud shoes, Lululemon clothing and diamonds. This development positions the U.S. as a leader in decarbonizing different sectors, and shows that economic growth and reducing emissions go hand-in-hand. However, realizing the full scale of this $1 trillion opportunity requires a policy framework that unleashes the private sector to innovate and helps solidify the U.S. as a global leader in emerging, carbon-based markets.

Carbon utilization is a space that has also garnered a lot of bipartisan support over the years. The foundation for this success was laid in the Energy Act of 2020 and signed into law during President Trump’s first administration, supporting the research and development of carbon management technologies. Building on that momentum, the One Big Beautiful Bill Act of 2025 provided parity in the Section 45Q carbon capture tax credit, ensuring that American innovators utilizing CO2 for EOR and other commercial products are finally on a level playing field. With this commonsense policy in place, American entrepreneurs finally have the long-term certainty needed to deploy capital and build the next generation of industrial energy leaders right here on American soil.

The best part is that American ingenuity is starting to deliver results. Companies across the country are already utilizing these technologies to turn carbon into a competitive advantage. Here are a few examples of American-led innovation in action:

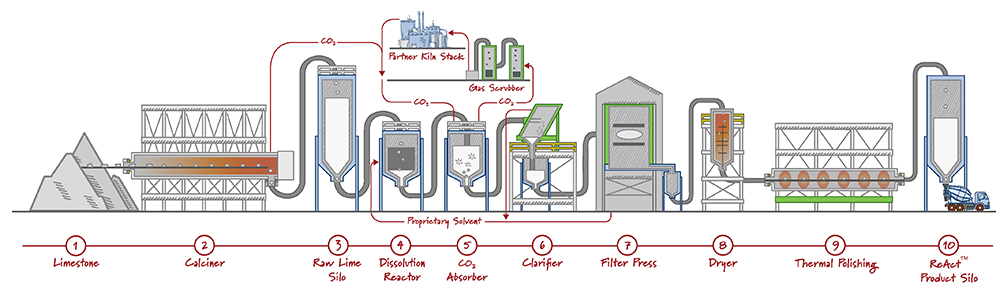

One of the most transformative areas of carbon utilization is in industrial materials. Captured CO₂ is increasingly used as a feedstock to create building materials, polymers, textiles and advanced carbon products, supporting our infrastructure and economy while reducing industrial emissions. California-based Fortera has created a cement process that captures CO₂ emissions directly from the cement plant kiln and mineralizes it into a stand-alone cement. Fortera’s process can be added onto existing cement production facilities, enabling a retrofit approach that minimizes disruption while dramatically reducing emissions. The resulting products either enhance or replace traditional cement, offering cost and performance competitiveness that makes low-carbon building materials a scalable reality.

Fortera’s new plant in California, co-located with CalPortland’s cement plant, demonstrates this in action, capturing industrial CO₂ and transforming it into cement with up to 70% lower CO₂ emissions. With recent investment from Microsoft, the plant plans to scale production from 15,000 tons to 400,000 tons of cement per year, which is enough to support the construction of over 20,000 homes. They recently completed their first major pour, supplying low-carbon cement to Simpson University, located near the plant. Using carbon in industrial materials enables America to continue to build while lowering emissions.

Fortera – Low-Carbon Cement

Source: Fortera

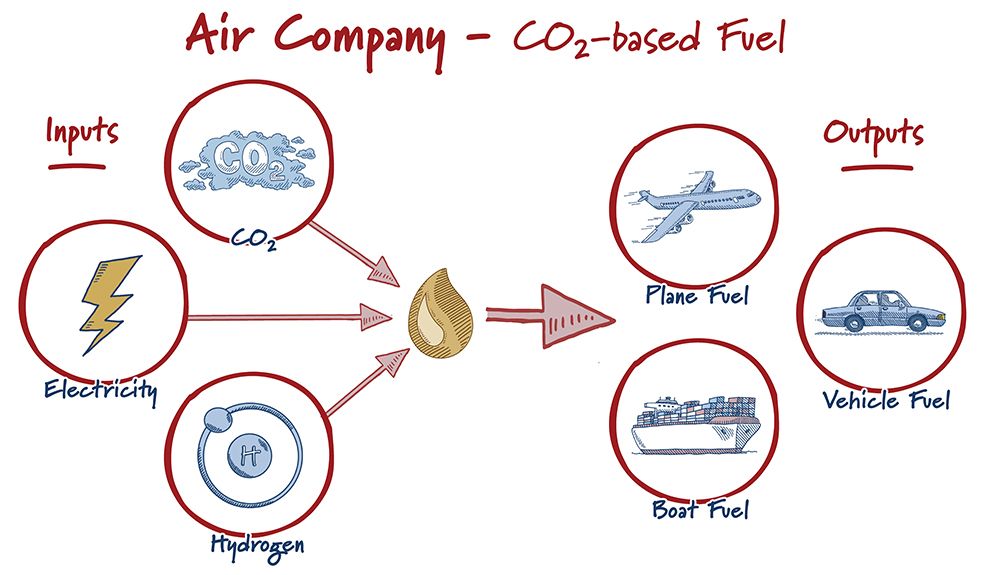

Another exciting area of application for captured carbon is the production of synthetic aviation fuel directly from captured CO₂. AIRCO, formerly Air Company, is leading the charge with its technology – an advanced carbon conversion platform that transforms captured carbon dioxide and hydrogen into high-performance synthetic fuels. These fuels are not only viable for commercial aviation but also tailored for defense applications, given their on-demand production in remote areas, supporting vehicles across air, land, and sea through a strategic partnership with the U.S. Department of War. They have also partnered with major airlines, including Virgin Atlantic and JetBlue, and recently unveiled a fuel plant in New York City. AIRCO’s fuel is able to seamlessly drop-in as a solution and meets all jet fuel requirements. By using CO₂ as a primary feedstock for a valuable asset like jet fuel, America can diversify the supply chain, supporting energy security and national defense and reducing emissions simultaneously.

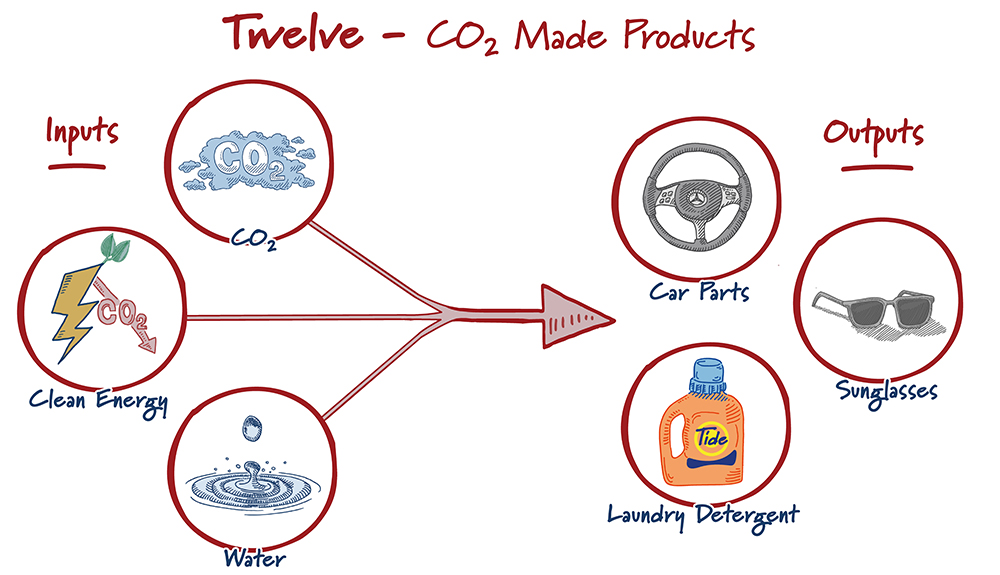

The “Made in China” tag on everyday items has become all too familiar, but utilizing CO2 in the manufacturing process could bring back the supply chain for more products to be “Made in USA.” Twelve’s CO2Made products are made using chemicals and materials from captured CO₂. These products are functionally identical to their traditional counterparts, making them easy drop-in replacements. Using locally captured CO2 in the manufacturing process also promotes domestic production of many products that are usually manufactured overseas.

Twelve has already partnered with household name brands, including Procter & Gamble, Mercedes, and Shopify, to develop CO2Made versions of existing products, as well as NASA and the U.S. Air Force to deploy its synthetic fuel. Twelve has raised over $900 million in funding to commercialize its technology and build its first plant in Washington. They have recognized the growing demand for low-emissions products and are capitalizing early on the increasing value of CO2 as a commodity.

As the U.S. competes with China and others for energy dominance and a competitive advantage in products, utilizing CO2 to expand domestic supply chains and create resources for energy production is essential to getting ahead. Countries and companies that leverage advanced energy solutions to create energy abundance and product reliability in a time where demand for infrastructure and power is on the rise will be set apart in the global tech race. Innovations that integrate CO2 utilization seamlessly into existing industries will simultaneously strengthen and decarbonize the economy.

While 45Q parity has leveled the playing field, further research and development, and public-private partnerships are needed to connect American industry to these emerging markets. To fully capitalize on captured CO2 and turn it into an economic advantage, bipartisan solutions like legislation introduced by Senator Collins (R-ME) in the 118th Congress are needed to guide innovation, build infrastructure and bring competitive technologies to market. The 119th Congress has the opportunity to advance these bipartisan blueprints to power the next generation of American carbon commodities and reduce global emissions.