The basic concrete-making process has largely remained unchanged since the Roman Empire mixed the first batch. Today, cement and concrete are the literal building blocks of modern society, used in everything from roads to buildings. Since this time-tested recipe creates a significant amount of carbon dioxide emissions as a byproduct, efforts are underway to reduce the product’s carbon footprint. Around the world, about eight percent of carbon emissions can be traced back to cement and concrete production. Globally, these emissions will continue accumulating as demand for cement and concrete is expected to grow by 12-23% by 2050 due to population growth and urbanization, mostly in developing countries. Said another way, the world is expected to build a New York City’s worth of concrete every month for the next 40 years.

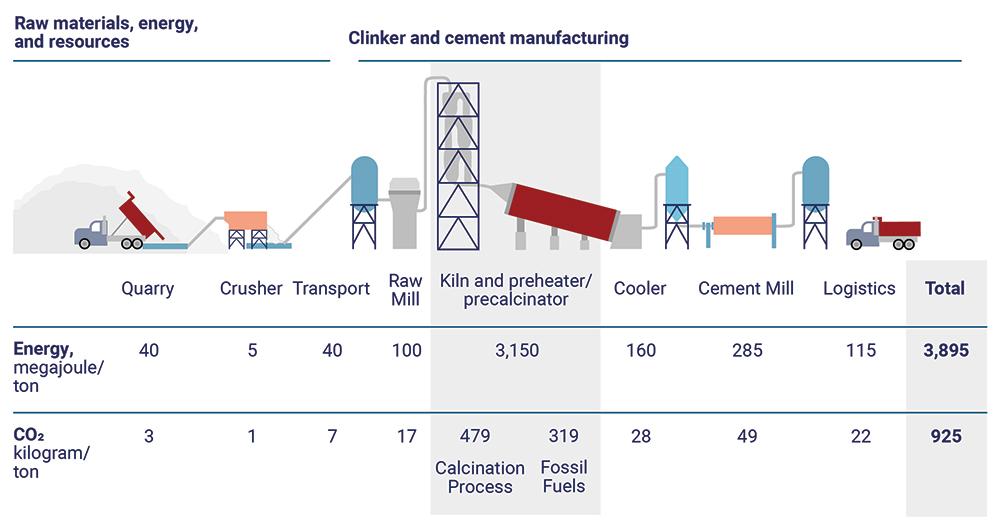

77% of concrete emissions arise from cement production, and cement production creates carbon dioxide emissions in two main ways. First, it requires ultra-hot heat, typically provided by fossil fuels. Second, it produces “process emissions” from baking limestone (a necessary ingredient in cement). Similar to how an elementary school science project volcano creates carbon dioxide from mixing baking soda and vinegar, baking limestone also creates carbon dioxide. Thus, managing cement’s process emissions with the time-tested recipe necessitates some amount of carbon capture and storage (CCS) – even if fossil energy combustion was removed. Cement paired with CCS can reduce cement emissions by 63 million tons of CO2 annually, more than half of US cement emissions.

Source: McKinsey

Tailored CCS Research, Development and Demonstration (RD&D) for Cement Facilities- Due to the importance of process emissions in cement and concrete’s overall emissions, CCS to capture and store avoidable emissions is a key technology that needs to be supported to reduce costs, improve performance, and deploy at scale. ClearPath recommends tailored CCS research, development and demonstration (RD&D) for cement facilities. One lever is through implementing the Energy Act of 2020. The bipartisan bill includes several new authorizations for the U.S. Department of Energy (DOE) to support low-carbon industrial manufacturing projects. It sets a goal for the Department to fund at least two carbon capture demonstration projects at industrial manufacturing facilities.

Diversify CCS RD&D- The U.S. carbon capture research program is almost exclusively focused on power plant applications, although it has begun to include some industrial sector work. More dedicated research is needed to advance industrial sector applications, especially since industrial applications such as ethanol and hydrogen production are the lowest-cost carbon capture applications present on the market today.

Implement Recently Enacted Policies- The 45Q and 48C tax credits must be geared to advance cement carbon capture through Treasury guidance that does not discriminate against cement carbon capture projects. Furthermore, the Office of Clean Energy Demonstrations (OCED) in the DOE responsible for administering the Advanced Industrial Facilities Program must be advised to fund cement CCS projects to drive costs down and mature the technology. According to the DOE, at least 3-5 demonstrations of cement CCS plants are needed from now through to 2025 to de-risk the technology and prove out the economics.

Research Alternative Chemistries and Production Methods for Cement & Concrete- In cement, this involves researching alternative chemistries and producing “drop-in” replacements that are chemically similar to traditional, carbon-intensive cement, but with lower emissions. In concrete, this involves research into cement replacements and materials that reduce the amount of cement required for a unit of concrete. It also includes looking at different ways to re-engineer the concrete production process to reduce its environmental footprint, including using electrochemistry to eliminate combustion and process emissions from the cement production process. Research can be boosted by aligning federal sustainable materials research. Multiple federal agencies conduct research related to environmentally friendly infrastructure and these programs should be coordinated to improve efficiency and leverage resources.

Incentivize The Shift to Performance Specifications- Currently federal and state Departments of Transportation (DOT) follow and set requirements that specify the chemistry, type, and volume of materials that can be used and are known commonly as prescriptive specifications. Prescriptive specifications block and slow the adoption of low-carbon cement and concrete that do not meet prescriptive requirements. Policies can incentivize and encourage states and municipalities to add performance specifications that do not restrict, broadly speaking, the types of materials. Instead, they set targets for structural performance that must be met. Performance specifications enable the increased adoption of materials for both short-term and long-term emissions reduction. In the short-term, they increase the use of cement substitutes known as supplementary cementitious substitutes (SCMs) in concrete production. SCMs include industrial by-products such as steel slag and coal fly ash, are commercially available, and can be deployed with minimal plant retrofits. According to the DOE, increased SCM usage is one of the levers for the cement industry to reduce emissions 30-40% by 2030. In the long-term, performance specifications pave the way to use cement/concrete made from novel inputs and chemistries.

Pilot Demand-Side Programs for Low-Carbon Cement & Concrete- The costs of decarbonizing cement and concrete fall unequally across the value chain. Even with the $85/ton credit in the 45Q tax credit, cement CCS is still not profitable for most cement manufacturers, who face higher operational and capital costs in competitive commodity businesses. At the same time, final end-users or building owners only face a 1-2% increase in the final project cost from using low-carbon cement and concrete. Policy support must not only reduce supply-side costs and risk but also stimulate increased demand for low-carbon cement and concrete to provide market certainty and revenue for cement and concrete manufacturers to invest in decarbonization. Federal and state agencies such as the Department of Transportation are well-positioned to pilot these demand-side policy measures because of their market power - federal, state, and local spending equals roughly 40% of total U.S. procurement of concrete for construction.

One type of demand-side incentive includes advanced market commitments (AMCs). AMCs are price and/or volume guarantees that the federal government can offer to producers of low-carbon cement and concrete before production, reducing investor risk and catalyzing investment. AMCs have been successfully implemented by NASA to develop a private spaceflight industry in the US and reshore rocket re-supply capabilities and by private companies to jump-start the carbon removal industry. AMCs are well-suited to advance technology-neutral innovation by maximizing ‘shots on goal’ through funding a portfolio of technology and project types. AMCs function as fiscally responsible policies if fund disbursement is tied to projects reaching technical and commercial milestones or delivering products of the required quality on time.

Demand-side support can also come from procurement of low-carbon cement and concrete from federal construction materials. Federal agencies such as the Department of Transportation (DOT) or the General Services Administration (GSA) spend billions annually on cement and concrete. Their purchasing power can be leveraged to procure low-carbon cement and concrete.

Source: Heidelberg Materials

Source: This Is Construction