Hydrogen is the smallest atom in the universe. Yet, this tiny molecule has enormous potential to unlock some of our most significant energy challenges – electricity grid resilience, energy storage and clean manufacturing. Hydrogen, in its natural state, is really two hydrogen atoms linked together, and in that link is where energy is stored. Like an electron flowing through a transmission line, hydrogen holds energy that moves between the electricity, transportation and manufacturing sectors. Watch a video that further explains how hydrogen functions here.

Hydrogen is used widely today as a chemical in agriculture, chemical production and oil refining. The United States produces around 10 million metric tons of hydrogen, enough to power 2.4 million transcontinental flights for a Boeing 747. By 2050, hydrogen has the potential to decrease 7 Gt of global CO2 emissions each year. However, only a fraction of U.S. hydrogen production today is considered low-emissions.

The innovation potential of hydrogen lies in its use as energy in new markets, such as energy storage, heavy-duty vehicles and manufacturing applications. Recent legislation, like the bipartisan Investment Infrastructure and Jobs Act of 2021 (IIJA) $8 billion Regional Clean Hydrogen Hubs, has helped accelerate the demonstration and deployment of low-emissions hydrogen while securing American leadership. To meet our clean energy goals, emissions reduction in the existing hydrogen infrastructure and significant new deployment of low-emissions hydrogen must be realized to meet the demand of new markets.

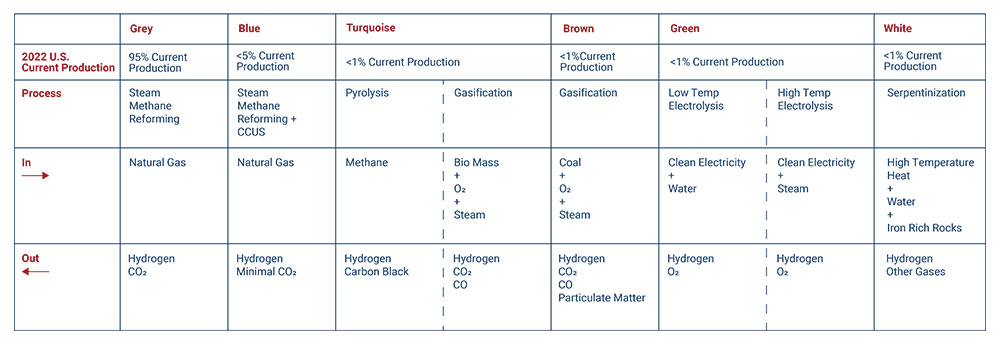

Hydrogen, in reality, is a colorless gas, but it is talked about widely using six color classifications: grey, blue, turquoise, brown, green and white. Today, adding carbon capture to existing hydrogen production facilities, a kind of blue hydrogen, is the least-expensive, nearest-term option to decarbonize existing production.

Production Methods – Hydrogen Rainbow

Source: DOE Pathway to Commercial Liftoff: Clean Hydrogen

Grey and Blue hydrogen are made by heating a natural gas and steam mixture, which produces CO2 as a byproduct. The grey hydrogen process allows CO2 to escape into the atmosphere, but the blue hydrogen process captures, utilizes or stores CO2. Carbon capture is already commercial, with facilities capturing millions of tons of CO2 worldwide – including in the United States.

Turquoise hydrogen is produced through either gasification or pyrolysis with carbon capture. Gasification means that biomass, such as used paper or waste from crops, is heated to release hydrogen gas and produces CO2 as a byproduct. The other process, pyrolysis, heats methane (i.e., natural gas) in a container without oxygen to separate the hydrogen and carbon atoms. Because there is no oxygen in the mix, carbon in the pyrolysis process does not turn into CO2. Instead, it becomes carbon black, a solid used to manufacture tires, mascara, water filters and more. One innovative American company producing hydrogen through pyrolysis is Monolith, which received a $1.04 billion conditional commitment from LPO to expand its facility in Nebraska.

Brown hydrogen is produced through the gasification of coal, which means that coal is heated with oxygen and steam to release hydrogen gas. This process also releases CO, CO2 and particulate matter as byproducts.

Green hydrogen is produced through electrolysis, which uses electricity to separate the oxygen and hydrogen atoms in water and is powered by low-emissions electricity sources. Producing hydrogen from electrolysis is possible regardless of the electricity source. Still, hydrogen is considered green only if the electricity is produced from a low-emissions energy source, such as nuclear, geothermal, hydropower or renewable energy.

White hydrogen naturally occurs and is found in underground deposits. The process that forms geologic hydrogen is called serpentinization, during which water reacts with iron-rich mantle rocks at high temperatures to make hydrogen. Typically, other gasses are present in the hydrogen deposits, with N2, CH4, He and other noble gasses being the most common. In February 2024, the DOE’s Advanced Research Projects Agency-Energy (ARPA-E) selected 16 projects to receive a total of $20 million in funding to research the production of geologic hydrogen through stimulated mineralogical processes, meaning that there is potential to stimulate the production of white hydrogen.

Storage

There are multiple ways to store hydrogen. One method is underground hydrogen storage, limited to excavated salt caverns and lined hard rock storage near production sites. Luckily, storage regions tend to overlap with production regions. This increases the viability of this storage method. Additionally, gaseous and liquid storage containers are currently used for industrial applications. Research, development, and deployment (RD&D) are needed to reduce costs, improve efficiency, and increase scalability for hydrogen storage.

Delivery

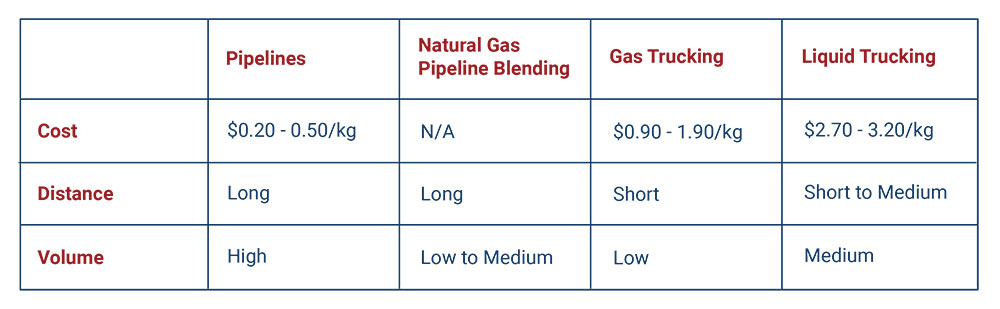

Currently, there are four main methods to deliver hydrogen:

Comparison of Hydrogen Delivery Methods

Source: DOE Pathways to Commercial Liftoff: Clean Hydrogen

Although smaller amounts of hydrogen in natural gas pipelines are considered safe, experts say blending larger ratios requires further research for feasibility. Natural gas infrastructure is more readily impacted by embrittlement and leakage when hydrogen is in the mix.

Regardless of how hydrogen is produced, it can be used in many applications, including as a feedstock for industry, a fuel for vehicles or power plants, or burned for heat.

Industry

Hydrogen has been used in American industries since the 1950s and is most widely used in refining (55%), ammonia and methanol (35%), and metals (8%). Ammonia, a component of fertilizer, is synthesized using hydrogen. Refineries use hydrogen to reduce the sulfur content in diesel fuel. It is also being developed as a feedstock to reduce CO2 emissions from the steel production process, making it an alternative to metallurgical coal. Also, hydrogen can be burned as a high-temperature heat source in heavy industry applications like cement and concrete manufacturing.

Natural Gas Blending

Today, hydrogen can be blended with natural gas in small quantities and used in many similar applications, such as home heating, high-grade heat for industry, and turbines for power generation. Turbine manufacturers design products that can co-fire hydrogen and natural gas or burn 100 percent hydrogen. Duke Energy will build and operate the U.S.’ first system capable of producing, storing and combusting 100% clean hydrogen in a combustion turbine.

Fuel Cells

Fuel cells work the opposite of electrolyzers and use hydrogen to make water and electricity. Small fuel cells can be used in vehicles, and large ones can be used for reliable electricity, such as a hospital or data center backup generator.

Energy Storage

Hydrogen is an emerging option for long-duration energy storage. Like natural gas, it can be stored for long periods and transported over distances. PG&E, in partnership with Energy Vault, is building the most extensive clean hydrogen long-duration energy storage system in the U.S., which can power about 2,000 electric customers for up to 48 hours.

The vast hydrogen ecosystem has the potential to decarbonize many clean energy technologies. Supporting these many decarbonization pathways requires significant coordination across offices in the DOE and other federal agencies. The DOE released the Pathways to Commercial Liftoff: Clean Hydrogen report and the U.S. National Clean Hydrogen Strategy and Roadmap in 2023. These strategies have common veins: the production cost of low-emissions hydrogen must be lowered to be cost-competitive, and successful demonstrations are important to scale these technologies.

Hydrogen Interagency Taskforce (HIT)

In August of 2023, the Hydrogen Interagency Taskforce (HIT), which is a partnership led by the Hydrogen and Fuel Cells Technology Office (HFTO), was announced to enact a coordinated approach for the advancement of clean hydrogen. The HIT consists of three working groups: “Supply and Demand at Scale,” “Infrastructure, Siting, and Permitting,” and “Analysis and Global Competitiveness.” The DOE will focus on RD&D, bolstering supply chains, developing a domestic and international market, and financing hydrogen projects as authorized by the IIJA. Non-energy agencies are also involved. The DOD, DOE and Homeland Security are developing an advanced fuel cell truck prototype, dubbed H2@Rescue, to provide zero-emissions power, heat and water to disaster sites.

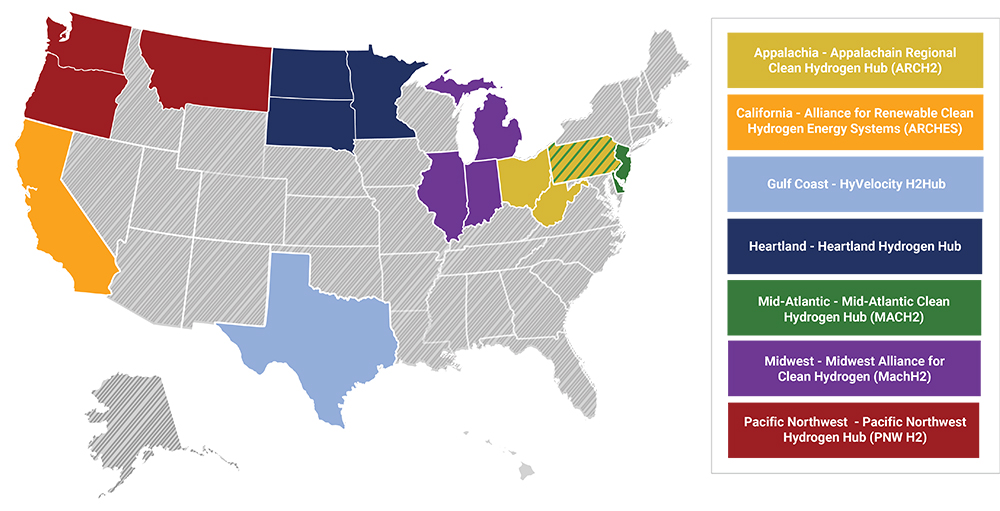

Regional Clean Hydrogen Hubs (H2Hubs) Program

In October 2023, the DOE preliminarily selected seven public-private partnerships to receive awards for the H2Hub program authorized by the IIJA. If implemented and supported properly, the $8 billion program will help launch the nascent hydrogen industry forward and decrease the cost of clean hydrogen.

States Awarded Hydrogen Hubs

Map of states selected for the DOE H2Hub’s award negotiations. Negotiations are expected to be completed in Q2 of 2024.

Source: DOE H2Hubs Press Release

Other IIJA Clean Hydrogen Programs

The IIJA also authorized $1 billion for the Clean Hydrogen Electrolysis Program, in which the DOE will establish an RD&D program to improve electrolyzers’ efficiency, durability, and cost and bring them to commercialization. A complementary program, Clean Hydrogen Manufacturing and Recycling RD&D Activities, was authorized for $500 million in the IIJA for the DOE to create innovative approaches to increasing the reuse and recycling of clean hydrogen technologies. The DOE released a Request for Information (RFI) in February of 2022, asking stakeholders for ideas on program structure and thoughts on the current electrolyzer landscape. The DOE selected both programs’ first tranche of projects simultaneously in March of 2024. The $750 million in joint funding will go to 52 projects across 24 states to support electrolyzer manufacturing, supply chains and components; fuel cell manufacturing and supply chains; and a recycling consortium.

Hydrogen has the potential to be an innovative solution to decarbonize the power and manufacturing sectors while making American energy cleaner, more secure and reliable. However, the simultaneous development of the hydrogen value chain (i.e., production, storage, end-use) is a barrier to deployment due to varying technological readiness levels, lack of long-term offtake and the need for dedicated hydrogen infrastructure. To meet emissions reduction goals, the following policies are needed to reach the widespread adoption of hydrogen.