Posted on August 3, 2017 by Savita Bowman

The technology is widely recognized as a critical emission reduction technology because it can significantly reduce emissions from new and existing fossil power plants, mitigate industrial emissions (e.g. cement, steel and ethanol), and achieve negative emissions under certain applications.1

Economic Potential

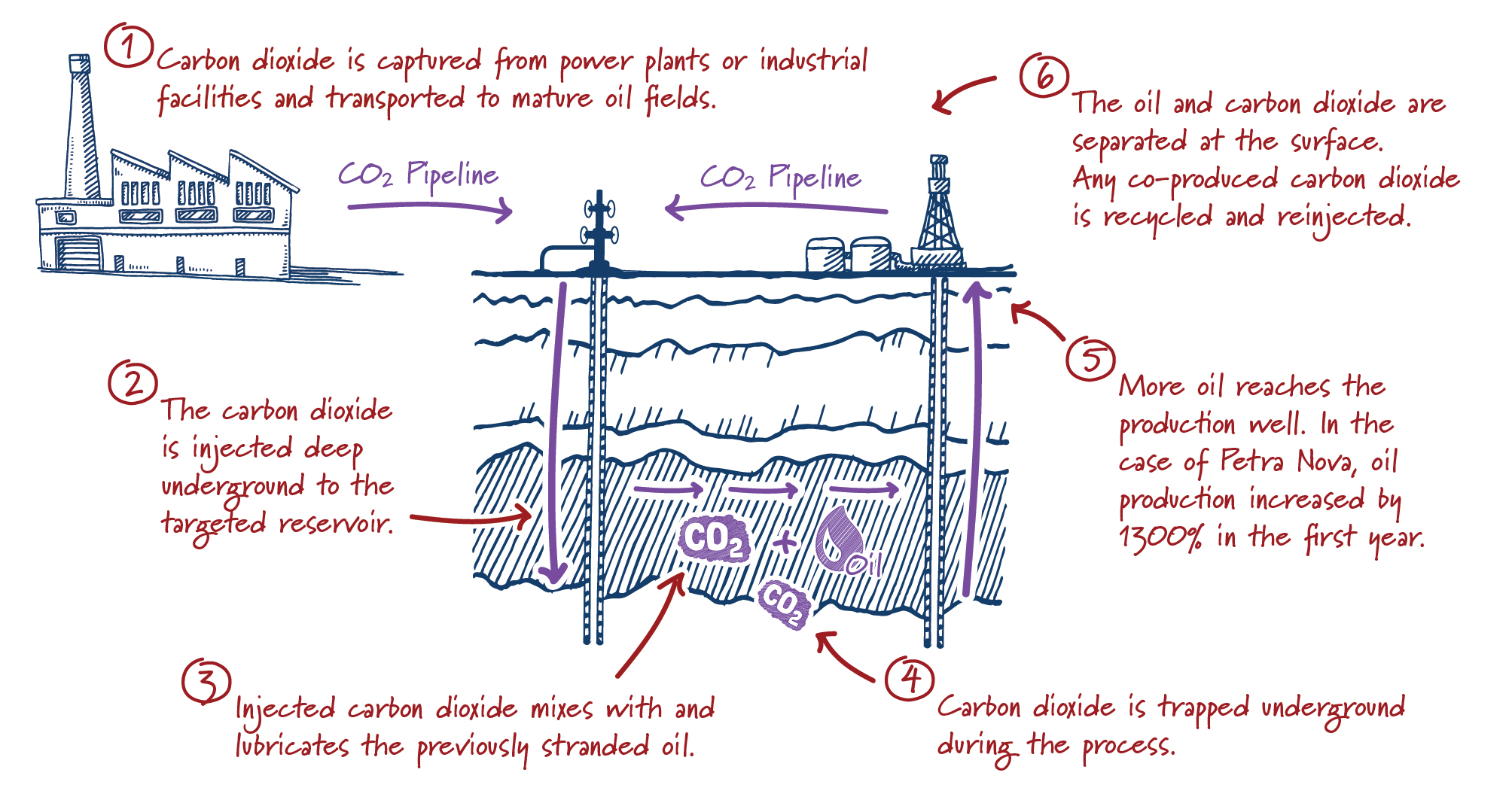

Carbon capture projects were first deployed in the United States nearly half a century ago during the energy crisis. Petroleum engineers discovered that injecting carbon dioxide into mature oil fields often increases oil production by increasing reservoir pressure and increasing miscibility, in a process called “enhanced oil recovery”.2 Over 5,000 miles of carbon dioxide pipelines3 have been built across the United States, directly contributing to about 3% of total United States oil production.4 Carbon dioxide is so useful for oil production, naturally occurring carbon dioxide is actively mined for and sold like natural gas to producers.

Source: NRG5

Applying carbon capture systems to power plants is a more sophisticated and expensive process. To date, only two carbon capture projects in the world have been installed at a power plant.

One of the two – NRG’s Petra Nova project- captures up to 5,000 tons of carbon dioxide each day from a Texas coal plant. The carbon dioxide is then sold to an oil company that pump them underground where it helps produce oil, in a process called “enhanced oil recovery”. The project is expected to increase production from 300 barrels per day to 15,000 barrels. Multiple studies have shown enhanced oil recovery results in low-carbon barrels of oil.6,7

Systems are typically designed to capture 90% or more of total carbon dioxide emissions, consistent with deep decarbonization. Carbon capture is also an economic decarbonization option. The latest Intergovernmental Panel on Climate Change assessment report found meeting Paris Agreement targets were 138% more expensive when carbon capture was not included as a mitigation option.8 The International Energy Agency study estimates the world will need 2,500 large carbon capture facilities to meet Paris targets.9 Similarly, Shell estimates 10,000 large facilities are needed in the next 50 years.10 Today, there are only about two dozen.11

According to the International Energy Agency, only 4 of 37 clean energy technologies are not on track.12 Carbon capture projects are not an exception: less than two dozen large carbon capture projects have been built around the world.13 Systems have historically been applied at natural gas and bioenergy facilities, where the flue gas streams contain higher concentrations of carbon dioxide and capture costs are lower. In some industries, such as cement production, carbon dioxide is created as a chemical process and carbon capture is the only option for decarbonization.14

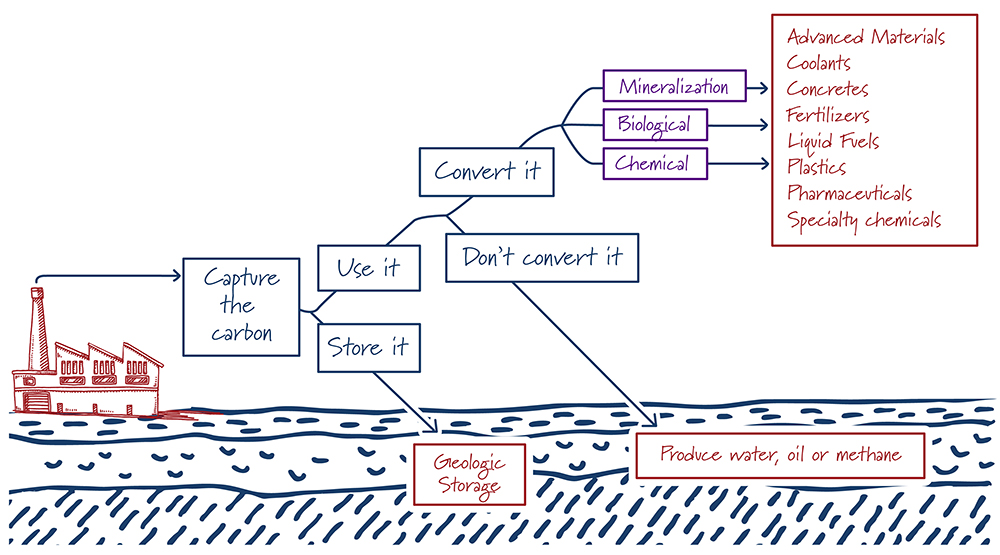

Source: ClearPath15

Projects face a number of hurdles including unique environmental permitting requirements, financing challenges associated with high capital cost and often first-of-a-kind commercial projects, and the slow development of climate policies around the world. Although carbon capture technologies have been traditionally underfunded, receiving about one hundredth of all clean energy investment, a recent bipartisan tax credit for carbon capture projects has stimulated commercial interest in new projects.16

Private-public partnerships are currently underway to improve the economics of carbon capture projects by reducing the costs of carbon capture and carbon storage techniques.