Posted on May 8, 2024 by Rafae Ghani

The industrial sector, including cement, steel and chemical manufacturing, produces the building blocks of society. Industrial products are everywhere: in buildings, the roads you travel on and the products the U.S. uses daily. However, the industrial sector is a major source of U.S. emissions and is poised to be the largest emitting source by 2035.

In March 2024, the Department of Energy (DOE) launched the most significant industrial decarbonization program to date, announcing $6 billion in funding for 33 selected projects across 20 states under the Industrial Demonstrations Program (IDP). The IDP provides federal grants to demonstrations of industrial decarbonization across heavy industrial sectors. It was authorized by the Clean Industrial Technology Act (CITA) as part of the Energy Act of 2020. The Infrastructure Investment and Jobs Act (IIJA) and 2022 tax law provided the funding to DOE’s Office of Clean Energy Demonstrations (OCED) to oversee implementation.

This blog will highlight how these awards can kickstart a clean industrial revolution to reduce emissions while strengthening American manufacturing.

Sectoral Breakdown of Demo Funding and CO2 Emissions Avoided Annually

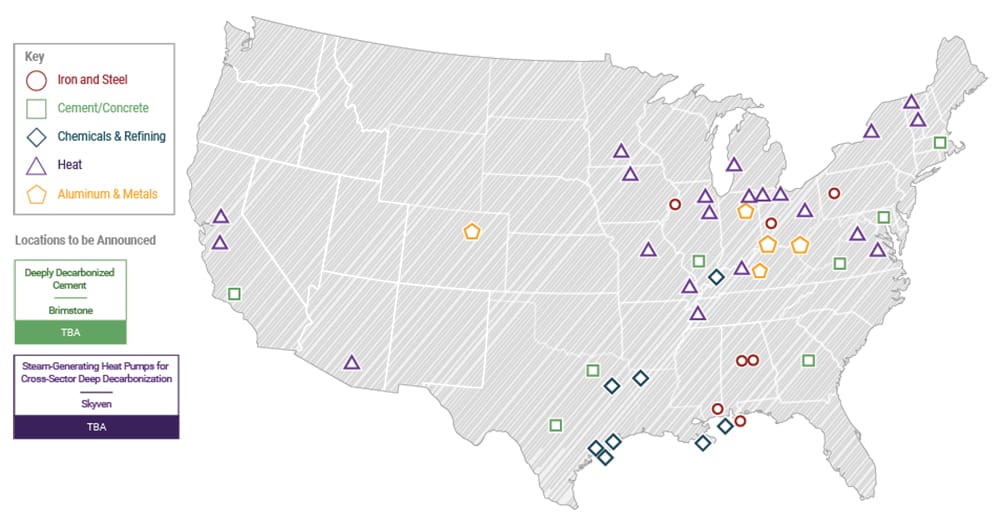

Map of Selected Projects

ClearPath wants to highlight four projects that showcase transformative technologies.

Cleveland-Cliffs Steel Corporation (Middletown, Ohio)

American steelmaker Cleveland-Cliffs was selected for up to $500 million in federal funding to replace a blast furnace with a hydrogen-ready direct reduced iron (DRI) furnace and two electric melting furnaces. Hydrogen replaces coal as the ingredient that transforms iron ore into iron.

Through this demonstration, Cleveland-Cliffs is decarbonizing the iron-making process, the largest emissions source in the iron and steel sector, responsible for 50% of all emissions. The Middletown demo will avoid more than one million metric tons of emissions annually, creating 170 permanent and 1,200 construction jobs while preserving the existing workforce.

The Middletown demo is one of the first large-scale demonstrations of integrated hydrogen-based steelmaking in the U.S., testing a decarbonization pathway that can be replicated across the remaining 13 blast furnaces in the U.S.

Heidelberg Materials US Inc. (Mitchell, Indiana)

Heidelberg has been selected for up to $500 million in federal funding to construct and operate an integrated cement carbon capture and storage (CCS) facility in Mitchell, IN. The facility will capture at least 95 percent of emissions from one of the nation’s largest cement plants, avoiding two million metric tons of emissions annually while creating 20-25 permanent jobs and 1,000 construction jobs.

Mitchell will be the U.S.’ first commercial-scale cement CCS facility, providing a template for the rest of the cement industry to decarbonize. Demonstrating cement CCS is critical because numerous industry and DOE roadmaps have identified CCS as a key cement decarbonization lever, contributing to over 30 percent of total emissions reduction. CCS is essential because Portland cement will remain an indispensable material, and ~60% of emissions are produced by chemical processes that cannot be reduced by using a clean fuel or energy source.

Sublime Systems (Holyoke, Massachusetts) and Brimstone (location TBA)

The demo program awarded federal funding to two U.S. cement innovators: $86.9 million to Sublime Systems and up to $189 million to Brimstone, creating nearly 200 permanent jobs and 450 construction jobs.

Both companies use novel production processes and non-limestone-based inputs to produce materials with nearly zero emissions that have been certified and passed industry standards.

The demo awards will build first-of-a-kind commercial facilities for both approaches, a necessary step to de-risk these technologies for investors and the construction industry. These awards can move the needle on cement decarbonization by demonstrating one of the few pathways to reach net-zero emissions and position the U.S. as a leader in next-generation cement production.

Strengthens American manufacturing: The demonstration program selections prove public sector investments can commercialize innovative technologies. This follows the bipartisan Energy Act’s and IIJA’s success in stimulating generational investment in increasing U.S. competitiveness and onshoring critical elements of the manufacturing supply chain. For example, Cleveland-Cliffs was also selected to expand clean manufacturing at the only facility that produces transformer-grade steel, helping resolve a nationwide transformer shortage in the medium term.

Incentivizes first-movers: These awards represent tangible investments in first-of-a-kind facilities that deploy technologies such as CCS and hydrogen in the industrial sector. Achieving net-zero industrial emissions is impossible without proving and scaling up these technologies. Therefore, public sector funding is crucial to de-risk investments that can provide a blueprint for other facilities to decarbonize.

Invests in transformative technologies: On average, the portfolio yielded a 77% reduction in emissions, highlighting how the funding selections have chosen transformative technologies and projects that can significantly reduce emissions.

Highlights the importance of funding early-stage RD&D: Six projects, totaling up to $775 million in industrial demonstration funding, use technologies incubated early at the Advanced Research Projects – Energy (ARPA-E). Their inclusion highlights how goal-oriented investments in early-stage clean energy RD&D turn into a success story to strengthen U.S. manufacturing.

This is just the first step: While an important milestone, these industrial demonstration selections only avoid 14 million tons of emissions annually, driving only a one percent reduction in U.S. industrial emissions. Additional funding is needed to stimulate private sector investment for meaningful emissions reduction.

The DOE should proactively remove permitting barriers: The federal government should expedite permitting for the selected projects. Currently, onerous permitting under the National Environmental Policy Act (NEPA) can delay putting steel in the ground. As a recent ClearPath report recommended, the DOE should extend its categorical exclusion for R&D projects to these demo projects ensuring rapid deployment.

A clean industrial revolution may be around the corner: The industrial demonstrations program proves that targeted clean energy innovation policy can help American industry pioneer a clean industrial revolution and reduce emissions, allowing America to lead.