U.S. House Committee on Science, Space, and Technology

Below is my testimony before the U.S. House Committee on Science, Space, and Technology, entitled "Now or Never: The Urgent Need for Ambitious Climate Action" on April 28, 2022.

Watch Jeremy’s Opening Remarks

Good morning Chairwoman Johnson, Ranking Member Lucas, and Members of the Committee. My name is Jeremy Harrell, and I am the Chief Strategy Officer of ClearPath.

ClearPath is a 501(c)(3) organization whose mission is to develop and advance policies that accelerate breakthrough innovations that reduce emissions in the energy and industrial sectors. We develop cutting-edge policy solutions on clean energy and industrial innovation, and we collaborate with public and private sector stakeholders on innovations in nuclear energy, carbon capture, hydropower, natural gas, geothermal, energy storage, carbon dioxide removal, and heavy industry to enable private-sector deployment of critical technologies. An important note: we are supported by philanthropy, not industry.

Thank you for the opportunity to testify today and for holding this important hearing. Climate change is an urgent challenge that merits significant action at every level of government and the private sector. The recent Intergovernmental Panel on Climate Change (IPCC) reports demonstrate the ramifications of insufficient action and the opportunity before us if the public and private sector partner to expeditiously deploy low-emissions technologies. Working Groups One and Two showed that climate change is occurring, is driven largely by global industrial activity, and that reaching net-zero emissions will be needed to avoid the impacts of climate change.

The most recent installment of Working Group Three considers the most effective ways to reduce and potentially reverse emissions going forward. The IPCC makes several key findings stressing that the world is not deploying existing clean energy technologies fast enough, and the world is not investing enough into the technologies needed to go all the way to net-zero.

The United States is in a unique position to lead global action while creating jobs in new industries, reasserting America’s global technology and resources leadership over Russia and China, and driving down global emissions. Technological innovation, the American entrepreneurial spirit, and targeted free market incentives have made the United States one of the most carbon efficient economies in the world.

There are countless examples across the energy and industrial sectors. A recent life cycle analysis conducted by the Department of Energy’s (DOE’s) National Energy Technology Laboratory on U.S. liquefied natural gas (LNG) exports shows that American LNG can be up to 30% cleaner than Russian natural gas. While Chinese steel is the third dirtiest in the world, American steel is among the cleanest in the world, with the second lowest CO2-intensity of any country. Emissions from mining support services in China, including many minerals required for deploying clean energy at scale, are over 5 times higher than if those activities were conducted in the United States.

The ongoing aggression by Russia underscores the need for the United States to both be energy secure and provide our allies access to technologies and resources they need to reduce their reliance on adversarial nations while reducing emissions. For example, nearly 50 countries have markets for advanced nuclear power, a potential ~$360 billion per year market opportunity, but Russia currently accounts for about two-thirds of reactor exports worldwide. It is essential that the array of innovative new American nuclear technologies nearing commercialization accelerate towards the global market. The United States can also be a highly competitive exporter of clean hydrogen to meet supply gaps in both the European Union and Japan. The U.S. has both a cost and energy security advantage relative to our Russian, Middle Eastern, and Australian competitors when exporting hydrogen produced from natural gas with a high rate of carbon capture. This is due to abundant U.S. gas supplies and current policy, like the 45Q carbon capture utilization and storage (CCUS) tax credit, which has no international equivalent.

The House Science, Space, and Technology Committee is uniquely positioned to drive new clean energy technology forward through investments in American ingenuity and research. I would like to highlight past strategies that have worked and the immediate steps that must be taken to both innovate and deploy at scale.

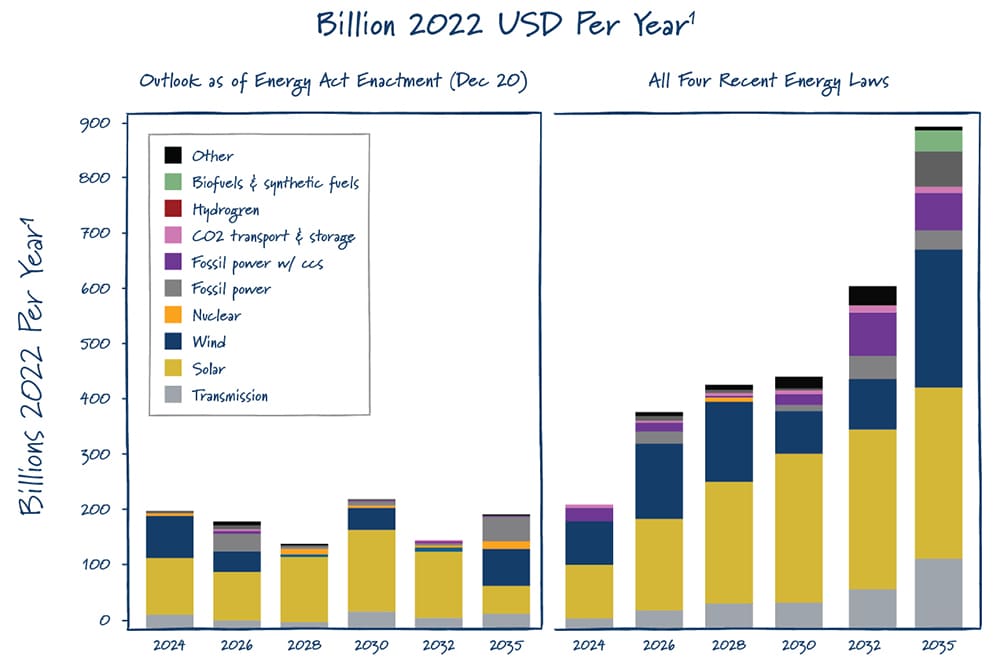

Most recently, your landmark bipartisan Energy Act of 2020 laid the blueprint for essential demonstration programs in a number of the areas highlighted by the International Energy Agency (IEA), the IPCC, and most other global energy and climate experts. This Committee continues to be critically important in developing policies that support new clean energy technologies to reduce emissions and grow the economy.

With this in mind, I will discuss four key priorities this Committee should keep in mind as it continues to lead on clean energy innovation:

- The continued importance of innovation to reduce emissions: The IPCC analysis conducted a decade ago found that extremely high levels of temperature rise could be possible by 2100. That is no longer the likely future, thanks to innovation in cleaner technologies. A focus on innovation-based policy makes clean energy more affordable and abundant. This increases economic growth, enhances American competitiveness, and is the best way for the United States to impact global emissions.

- The significance of implementing the bipartisan Energy Act of 2020 to commercialize key technologies: At the end of 2020, the House Science, Space, and Technology Committee collaborated with the House Energy and Commerce Committee and the Senate Energy and Natural Resources Committee to produce an end-of-Congress bipartisan package, including the Energy Act of 2020, that was the single largest clean energy and emissions reduction bill in over a decade. The legislation modernized energy research and development programs for the first time in 13 years and authorized numerous demonstration programs. Implementing those moonshot technology demonstrations is a critical task for further advancing energy innovation.

- The desperate need to modernize permitting: Unnecessary regulatory hurdles that slow down the deployment of innovative technology and necessary infrastructure, including the critical mineral supply chain, threaten the United States’ ability to significantly reduce our emissions and provide low-cost options to the rest of the world on an ambitious timescale. Right now, we can only build new clean energy and reduce CO2 emissions as fast as we can permit new projects. The mission ought to be “build cleaner faster,” not “duplicate and litigate.”

- Difficult-to-decarbonize sectors, especially in the industrial sector, merit increased attention: Several areas highlighted by the IPCC for further investment are not fully covered by the existing Energy Act demonstration programs. Areas that likely need additional authorization support include steel, cement, and chemicals; carbon dioxide removal technologies; and clean drop-in fuels such as hydrogen. This Committee wisely has taken bipartisan action on steel via the bipartisan Steel Upgrading Partnerships and Emissions Reduction (SUPER) Act. The steel sector is an area where the U.S. is particularly well-positioned given that American steel is among the world’s cleanest. Similar effort in other key industrial areas is also important.

The Role of Innovation in Reducing Emissions

Past investments in innovation, often led by this Committee, have paid off. Solar, wind, natural gas, and battery costs have fallen precipitously over the last decade. These technologies each contribute to reducing emissions, and none of them would be as cost-effective today if it were not for investments made by the United States over the last 50 years.

Take solar for example. In 2011, the U.S. The Department of Energy (DOE) launched the SunShot Initiative in partnership with industry and think tanks with the goal of reducing the costs of solar energy by 75 percent, allowing solar to compete at large scale with other forms of energy. The program was funded to support the development, commercialization, and manufacturing of advanced solar energy technologies. It was a smashing success: the cost of utility-scale solar was down from $0.28 per kilowatt-hour in 2010 to $0.06 per kilowatt-hour in 2017, achieving the 2020 SunShot goal three years ahead of schedule. Global solar demand has skyrocketed in part due to efforts like SunShot that reduced the cost of wide deployment.

And with the ongoing crisis in Ukraine, it goes without saying how important clean American natural gas is today, both domestically and to our allies around the world. There is no better example of how the public and private sectors can work together on clean energy innovation than the shale gas boom in America.

In the 1980s, Texas entrepreneur George Mitchell figured out how to break up shale rocks to release the natural gas stuck inside. This process, called hydraulic fracturing, initially got off the ground with support from DOE, which cost-shared R&D and demonstrations in the 1970s and 1990s, as well as tax credits from the 1980s to early 2000s.

These DOE projects included demos of hydraulic fracturing, horizontal drilling, 3-D seismic imaging, diamond headed drill-bits, and, ultimately, combined-cycle natural gas turbines. These now produce 24/7 reliable power that was more affordable than anything else on the U.S. grid over the past decade. Both this early stage investment, and the production tax credit, together more than $10B, expired as the technology matured.

Now we have a $100 billion annual shale gas market in America — not a bad return on investment. Continued investment in innovative technologies like carbon capture will further reduce the emissions profile of American-produced natural gas. Several companies are aggressively pursuing these technologies and 45Q will play an important role in meeting the innovation needs. Given the projected increase in global demand for natural gas, American-produced natural gas will be important to both facilitating lower emissions and improving global energy security.

Natural gas, solar, wind, and energy efficiency technologies have led to a 40 percent reduction in power sector emissions in the U.S. in the last 15 years, while GDP has grown more than 60 percent. This demonstrates the value of innovation for both the environment and the economy. But, more innovation is needed. While the costs of mitigation have come down in the previously mentioned areas, many of the technological solutions we need by 2050 are still too expensive to be commercially cost-effective in the near term. This is a clear place where government investment is warranted, and U.S. firms are well-positioned to lead.

The good news is that we know where to focus our efforts going forward. The report highlights several technology gaps for further innovation support that the United States is uniquely positioned to help solve. These gaps include methods for reducing emissions from heavy industry, carbon capture and carbon dioxide removal technologies, and clean hydrogen applications.

New frontiers in energy innovation are quickly emerging. One crucial technology area is clean hydrogen. Under the right circumstances, clean hydrogen produced from renewables, nuclear, or fossil energy with CCS can play a key role in reducing emissions in the industrial, transportation, and power sectors. The IPCC agrees, with the primary low carbon scenarios all including a significant energy-sector role for H2. Between the $8 billion in funding for clean hydrogen hubs provided to the DOE in the Infrastructure Investment and Jobs Act (IIJA), the 45Q tax credit, and the need for balancing excess renewable power, a number of new clean hydrogen production facilities are being established. Investments today will present immense domestic and international opportunities.

And the actions we take over the next decade are essential to quickly deploying those technologies in a cost-effective way. Every scenario that successfully reaches net-zero on a timeline sufficient to avoid significant impacts requires accelerated clean energy deployment through 2070. It is crucial to simultaneously deploy cost-effective solutions today while supporting R&D for the technologies needed tomorrow. Additionally, obstacles must be removed to allow clean energy projects to be permitted faster.

Accelerating these technologies will require robust public-private financing efforts. The last year has been an exciting time for clean energy startups and technological innovation — at least here in the U.S. BloombergNEF estimates that venture capital and private equity invested more than $53 billion in climate-related technologies. Corporate net-zero commitments were followed by more than $23 billion in corporate venture funds invested in businesses in the climate-technology sector. Deals were cut, MOUs were signed, and project partnerships were solidified that lay the foundation for an array of first-of-kind technology deployments eyeing mid-2020 operations. That’s all positive development, but it still is too low for the scale required to achieve deep emissions reductions by mid-century.

The question is how to drive down the cost of lower-emissions technology in a way that can help stimulate institutional and private capital in industrialized and nonindustrialized countries and to build those technologies at the pace required to meet the challenge. If these new technologies are developed, produced and commercialized here in the United States, our workforce will greatly benefit and American-made technology will help decarbonize those developing nations.

Implementing the Energy Act of 2020

As you know, one of the biggest advancements in clean energy and climate policy in over a decade is the monumental Energy Act of 2020. Thanks to the leadership of Chairwoman Eddie Bernice Johnson (D-TX), Ranking Member Frank Lucas (R-OK), and other advocates on this Committee, the United States has a wholly bipartisan, clean energy innovation roadmap that helps accelerate technology breakthroughs needed to meet emissions reduction goals.

The Energy Act modernized and refocused DOE’s research and development programs on the most pressing technology challenges — scaling up clean energy technologies like advanced nuclear, long-duration energy storage, carbon capture, and enhanced geothermal. Crucially, across all these technologies, DOE is now empowered to launch the most aggressive commercial scale technology demonstration program in U.S. history. The bill sets up a moonshot of more than 20 full commercial scale demos by the mid-2020s.

While you all know this bill well, I wanted to highlight five big successes from the Energy Act of 2020 that were led by Science Space & Technology Committee members.

First, the Energy Act repurposed the DOE Office of Fossil Energy to focus on carbon capture, utilization and storage technologies, and it authorized a comprehensive carbon capture R&D program, including six, large, first-of-a-kind demonstrations for natural gas, coal, and industrial facilities. In addition, it starts serious research and demonstration on carbon removal technologies via creative X-prizes on removing carbon dioxide from the atmosphere. Specifically, it included the following two bills:

- The Launching Energy Advancement and Development through Innovations in Natural Gas (LEADING) Act) directing DOE to conduct critical carbon capture research and development for natural gas power plant applications; and the

- The part of the Fossil Energy Research and Development Act provides DOE with new resources and tools to develop clean technologies, including reducing emissions from both coal and natural gas power plants, industrial processes, and direct air capture.

These policies, combined with the recent enhancements to the 45Q carbon capture utilization and storage credit, have furthered United States global leadership in the development of CCUS and driven dramatic project growth. 2021 was the largest single-year increase in the global pipeline, and the United States led the way with nearly half of the more than 70 new project announcements.

Second, it aims to reinvigorate advanced nuclear energy by formally authorizing the moonshot Advanced Reactor Demonstration Program (ARDP) and part of the Nuclear Energy Leadership Act (NELA). Moreover, advanced nuclear reactors cannot run without advanced fuel – which is why the Energy Act also creates a temporary program to develop a domestic supply chain to produce High-Assay Low-Enriched Uranium (HALEU), which is required by most advanced reactors under development today but is only commercially available from Russia, an option which is no longer tenable.

These policies were particularly important given that there are several new American nuclear energy technologies approaching commercialization that are smaller, pair flexibly with renewable energy, and are walk-away safe. Nearly 10 new advanced reactor licenses, from American entrepreneurs like Oklo, X-energy, TerraPower, Ultra Safe Nuclear Corporation, General Electric Hitachi, Kairos Power, and NuScale could come before the Nuclear Regulatory Commission (NRC) by 2025. All these companies are looking at building their reactors domestically over the next decade. Accelerating U.S. fuel security and driving down the cost of key components bolsters their ability to contribute to near-term reduction efforts.

Third, the Energy Act of 2020 establishes a comprehensive grid-scale storage demonstration program, effectively authorizing the Energy Storage Grand Challenge that former Energy Secretary Dan Brouillette launched at DOE and that now Secretary Jennifer Granholm has continued – along with a joint initiative with the Department of Defense (DOD) to develop long-duration storage technologies and a program to provide technical assistance to rural and municipal electric utilities. The bill also authorized the Better Energy Storage Technology (BEST) Act to reorient the federal grid-scale storage research, development, and demonstration program around ambitious technology goals necessary to facilitate important breakthroughs for the grid of the future. Related private sector growth has followed. In 2021, the U.S. built more than 3.5 GW of energy storage, which was more than double the amount installed in 2020. Notably, the Pacific Northwest National Laboratory broke ground on the Grid Storage Launchpad test facility on April 21 in Washington, a state of the art user facility to catalyze new grid-scale storage solutions.

Fourth, it includes significant provisions like the Advanced Geothermal Innovation Leadership (AGILE) Act for advanced always-on renewables like geothermal energy, including programs to demonstrate technologies to enable geothermal anywhere. There are exciting opportunities to transfer technologies from the oil and gas industry and demonstrate the co-production of critical minerals with geothermal energy. Since late 2019, 12 new geothermal power purchase agreements (PPAs) have been signed and companies have nearly 60 active developing projects and prospects across nine U.S. states. Meanwhile, California’s recent order for 1,000MW of geothermal power to enhance grid reliability by 2026 could dramatically increase the scale of geothermal development.14It represents a huge opportunity, and we were excited to see the Department launch the new cutting-edge technology demonstration program authorized by this Committee’s good work just last week.

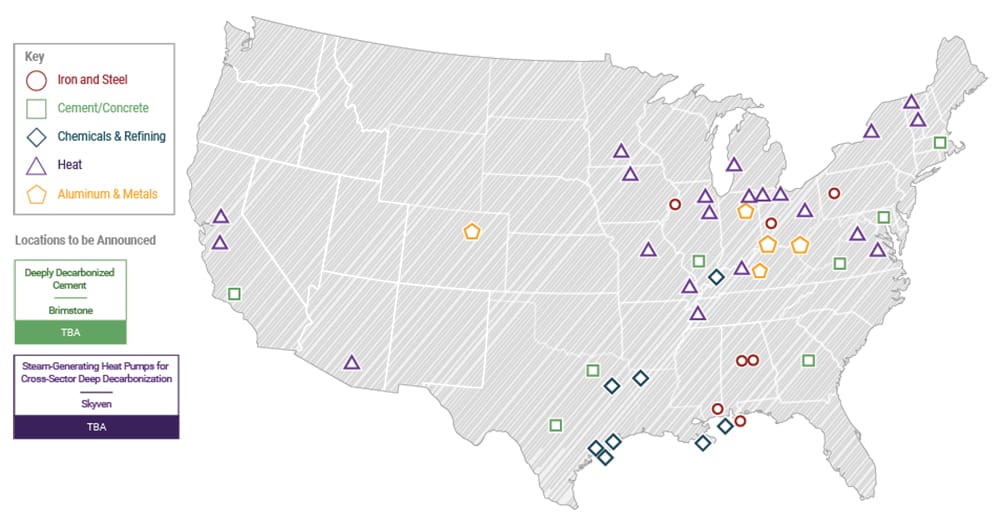

Fifth, the bill includes The Clean Industrial Technologies Act (CITA), which starts a comprehensive crosscutting clean industrial technologies R&D program to lower the cost of cleaner materials and manufacturing processes, especially for energy-intensive industrial sub-sectors such as steel, cement, and chemicals. As industrial emissions represent a growing share of global emissions, it is increasingly important to develop cost-effective technologies to reduce emissions in heavy industrial sectors. Fortunately, U.S. industries tend to be among the cleanest in the world, which is a competitive advantage we should leverage in the trade-exposed manufacturing sector.

In addition, the Energy Act of 2020 contains significant reauthorizations for solar and wind, critical minerals, grid modernization, the DOE’s Office of Technology Transitions, ARPA-E, and much more.

All of those policies and technological advancements are only as useful as implementation. The passage of the Infrastructure Investment and Jobs Act (IIJA) infused over $20 billion into the deployment of this road map. A few examples of what the IIJA included:

- $12 billion into CCUS programs, with nearly $2.54 billion specifically allocated for a demonstration program originally authorized by the Energy Act of 2020;

- $1 billion for a Clean Hydrogen Electrolysis Program, $500 million for a Clean Hydrogen Manufacturing program, $8 billion for Regional Clean Hydrogen Hubs, and reauthorization of DOE’s hydrogen activities;

- $3.5 billion for four regional direct air capture (DAC) hubs, each with the capacity to capture 1 million metric tons (MMt) of CO2 annually; and

- $500 million for industrial emission demonstration projects.

Importantly, if implemented correctly, these investments will be used to develop significant projects across the nation. It is important this Committee exercise its oversight authority over the next 18 months to ensure the Department is adhering to the deadlines directed by Congress while constructing programs that catalyze breakthroughs in these key clean technology focus areas.

Building Cleaner Faster

As we reimagine our energy and industrial systems using exciting new technologies, permitting modernizations must keep pace. The transition will require tens of thousands of miles of new pipelines carrying hydrogen and captured carbon dioxide from power plants and industrial facilities, new transmission infrastructure to carry electricity around an increasingly electrified country, and new nuclear reactors and power plants sited everywhere. This will be the largest continental construction project in history.

But there is a huge obstacle. Every single one of these clean infrastructure projects will need permits — often dozens of them — at the federal, state and local levels. A report issued by CEQ in June 2020 showed that the average environmental impact statement (EIS) took 4.5 years to complete, with one quarter taking upwards of 6 years. This timeline poses a significant risk to being able to reach the decarbonization goals recommended by the IPCC.

Given our shared goals, the federal government should be working with project developers at every level on permitting projects, not against them. Yet, the policies being put in place right now are restricting development. Just last week, the Council on Environmental Quality finalized its Phase 1 process on the National Environmental Policy Act Implementing Regulations Revisions. This rulemaking restored regulatory provisions from the pre-2020 NEPA regulations, which will open the door to more litigation, create interagency conflict, and cause undue delays and costs to critical clean energy projects. Not to mention the Federal Energy Regulatory Commission’s Draft Policy Statement released earlier this year that proposes sweeping changes to the evaluation of climate impacts from natural gas infrastructure. If we can’t build natural gas pipelines, how will we ever build CO2 and hydrogen pipelines?

We should set a big, bold goal to modernize regulations, improve the bureaucratic process, and build projects in less than two years. There are some common-sense measures that could be taken that would drive towards that goal.

Future reforms should prioritize projects that significantly reduce emissions, encourage siting of projects in areas that will minimize environmental impact and maximize economic benefit, such as brownfield sites, and accelerate legal dispute resolution. This can all be done without compromising environmental stewardship or the public’s opportunity to be involved.

Making the permitting process more efficient and eliminating unnecessary regulatory hurdles can both ensure stewardship of taxpayer resources and scale clean energy rapidly.

Expanding the Roadmap from Clean Energy to Further Innovation

There are two areas that the IPCC report, the International Energy Agency’s NetZero by 2050 report, and countless other analyses have clearly concluded are essential, and that this Committee could tackle: one, innovations for heavy industrial processes like steel, cement, concrete and chemicals; and two, greatly expanding technologies for carbon dioxide removal.

Industrial Sector

In 2020, emissions from industrial facilities were roughly as high as those from power plants, or 24% of all U.S. emissions. For the very first time, industrial emissions were neck and neck with the power sector, and it is likely that industrial emissions will remain higher than power sector emissions going forward. By 2030, industrial facilities are expected to be the top source of U.S. emissions, exceeding those from power plants and vehicles.

ClearPath’s guiding focus in the power sector is that achieving meaningful emissions reductions emissions will require cleaner and more affordable technologies. The same goes for the industrial sector. Let me explain.

First, we need more RD&D. There are already some policies we could build from, like the Clean Industrial Technology Act, which was included in the Energy Act of 2020. In addition, there is legislation that Congress should pass. Committee Members Anthony Gonzalez (R-OH) and Conor Lamb (D-PA) authored The Steel Upgrading Partnerships and Emissions Reduction (SUPER) Act, which is moving forward as part of the U.S. House’s America COMPETES Act of 2022. The SUPER Act strengthens the competitiveness of American manufacturing by developing technologies to reduce emissions of conventional steelmaking. Similar legislation could be adopted for cement and concrete.

We also need to create conditions for U.S. manufacturers to thrive. Some industries operate on very low margins and face immense international competition. We cannot disadvantage American industry by saddling them with extra compliance costs or more expensive technologies that drive manufacturing overseas. And more importantly, we should focus on returning manufacturing to the U.S., where production is more efficient and environmental performance is far superior to places like China or Russia. For example, two-thirds of U.S. steel is already produced using recycled steel and an all-electric process – and new processes are being demonstrated that make high-grade steel. American steel has the second lowest CO2-intensity of any country, and investors are clear they want clean and affordable steel. America can lead the steel industry to meet that demand.

However, many industries need heat at high-temperatures and intensities and largely cannot be electrified with renewable energy. It is also important to note that many American producers have recently built manufacturing plants that will remain in operation for decades, meaning it’s unrealistic to expect the industrial sector to fully decarbonize by mid-century. Similar to how the U.S. scaled up natural gas and solar power or how it is working to commercialize energy storage and advanced nuclear with the Grid Storage Launchpad and Advanced Reactor Demonstration Program, we can apply our talents for creating market-driven goals to commercialize innovative technologies that will reduce industrial sector emissions.

Carbon Dioxide Removal

Even with all of the exciting innovations, nearly all projections rely on some degree of carbon dioxide removal (CDR) to accelerate emissions reductions and offset residual emissions, like in difficult-to-decarbonize sectors like heavy industry. Long term, there will likely need to be removal of prior emissions to bring total emissions to be net-negative. According to analysis conducted by the National Academy of Sciences and the IPCC, the United States will likely need to remove about 2 gigatons of carbon dioxide every year by mid-century to reach net-zero — that's about 30% of U.S. 2017 greenhouse gas emissions. Globally, carbon removal could be more than 10 gigatons of carbon dioxide per year by 2050 with an additional removal capacity up to 20 GtCO2 per year by 2100.

Robust policy support is required, but policymakers are not starting from scratch here either. The bipartisan infrastructure bill included $3.5 billion to build direct air capture “hubs,” as well as over $100 million in funding for the Energy Act’s direct air capture prize competition.

There’s more that can be done to expand on the great carbon removal efforts in the Energy Act. One critical area is research and development into hybrid carbon removal technologies that combine the best attributes of natural and technological solutions.

There are policy ideas to build off of the Energy Act of 2020 by authorizing the first comprehensive federal carbon removal research and development program, and the IIJA, which invested $3.6 billion in direct air capture.

If the scope of DOE’s carbon removal and storage technology program was expanded, creating a path for DOE to research and evaluate the feasibility of a diverse portfolio of CDR and storage pathways, we would be able to quantify the net impact of various solutions rather than relying on the success of one specific technology. Carbon removal innovation, beyond traditional tree planting, is currently in its infancy; therefore, if investments are constrained to only a handful of recognized opportunities, then the most competitive and cost-effective CDR technologies may never be realized. One method would be to establish a pilot reverse auction purchasing program to accelerate carbon removal market commercialization.

We are seeing exciting private sector investments from the technology sector and the oil and gas sector. In recent years, companies with carbon reduction goals have invested more than $3 billion into carbon removal technologies. For example, Oxy Low Carbon Ventures has a planned direct air capture plant in Texas that could pull 500,000 tons of carbon dioxide out of the air annually. And just this month, a major investment spearheaded by finance company Stripe will put $925 million toward carbon dioxide (CDR) removal efforts. Stripe’s Frontier fund, backed by tech companies including Alphabet, Meta, and Shopify, will support the scaling up of CDR startups and reduce the cost of CO2 offsets.

Conclusion

This Committee has been at the forefront of Congressional efforts on clean energy innovation for many years. Importantly, you have an incredible record of bipartisanship marked by the enactment of the Energy of 2020.

ClearPath greatly appreciates what this Committee has accomplished, and we look forward to supporting your efforts in the months ahead.

Thank you again for this opportunity, and I look forward to the discussion.